How does RF connector manufacturers reduce cost?

There are many RF connector manufacturers on the market. Customers select manufacturers that will consider company's qualifications, product quality, delivery, sales service and other aspects, and most customers are care about the price. but how does RF connector manufacturers reduce costs?

The following details can be reduce some cost for RF connector manufacturers

1). Reduce cost in design process: RF connector manufacturers engineer generally prefer to design expensive connectors, so design structure, plating requirements and materials choosing can all be reduced costs. At the same time package design can be simplified, so it reducing costs.

2). Reducing costs in production efficiency: Many RF connector manufactures ’s worker have relatively large liquidity, which results in low production efficiency and increased labor costs. Manufacturers can regularly train workers to improve production proficiency and production quality control. Reduce labor costs

3). Cost reduction in transportation costs: Many RF connector manufactures ignore transportation costs during the quotation process. Some connectors are relatively heavy and bulky, and transportation costs are relatively expensive. You can negotiate freight with customers in advance and reduce the extra expenses of orders.

4). Purchasing raw material at one time: we suggest RF connector manufacture to purchase raw material at one time to reduce costs, and you can confirm purchasing order with customers in advance, so that you can use cheaper transportation methods to save costs.

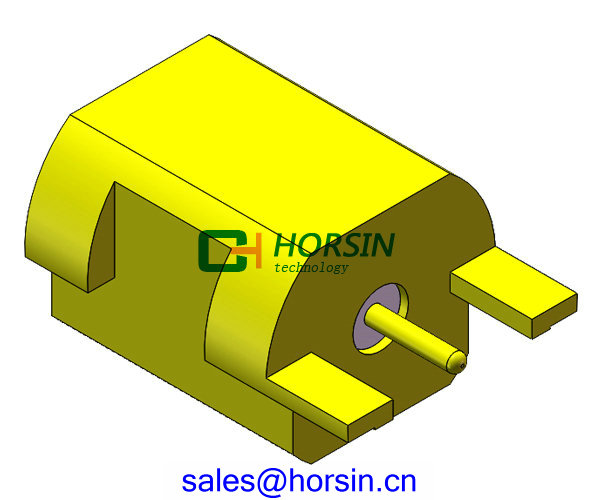

Horsin technology co,. ltd focus on 5G RF solutions and high quality connectors to meet customer’s requirement. Excellent electrical performance and suitable price to meet almost customer’s requirement all over the world . welcome contact our sales department to know more information .